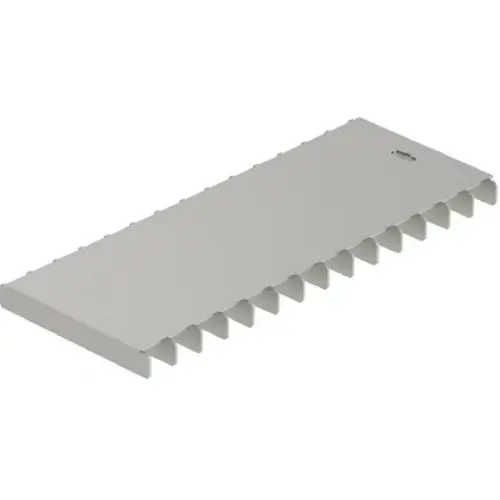

Customized Grating

- Model: BC-G200.500L

- Hygienic Ladder Grating

- Slot Grate

MEA® Grates are made from stainless steel 304 or 316L with options for passivation, electropolishing, and sandblasting. They feature hygienic anti-slip designs and various styles for indoor (EN 1253) and outdoor (EN 1433) use. Styles include mesh, ladder, wedge mesh, slot, hygienic ladder, and custom options.

Specifications

| Model No. | BC-G200.500L |

| Load Class EN1253 | ≤N250 |

| Width | 200 |

| Length | 500 |

| Material | 304/316L |

For comprehensive information, please see the document available for download below.

-

Description

Customized grating provides a drainage solution that adapts to the unique demands of each project. MEA engineers every grating from premium 304 or 316L stainless steel to meet specific dimensions, structural loads, grating styles, and finishes. Rather than adjusting your layout to fit a generic system, this product adapts to your design, whether in architectural landscapes, food production zones, or public transport hubs. Thanks to its tailored fabrication, it ensures smooth water flow, corrosion resistance, and exceptional stability—without compromising visual harmony or compliance.

You can select from mesh, ladder, wedge wire, or slot configurations to suit the drainage flow and safety requirements. With advanced finishing techniques like passivation, electropolishing, or sandblasting, MEA guarantees hygienic performance and long-term durability, even in aggressive cleaning or chemical conditions.

Features

-

Custom-made in 304 or 316L stainless steel for corrosion resistance

-

Personalized dimensions, slot patterns, and load capacities

-

Choice of surface finishes: passivated, electropolished, or sandblasted

-

Compatible with EN 1253 (indoor) and EN 1433 (outdoor) drainage standards

-

Anti-slip surfaces and clean edges to support safety and hygiene

Applications and Benefits

-

Integrates perfectly into kitchens, public plazas, laboratories, factories, and transport zones

-

Ensures seamless design coordination in complex architectural or mechanical layouts

-

Handles high flow rates while remaining easy to clean and maintain

-

Enhances design flexibility for curved floors, sloped drains, or non-standard openings

-

Prevents costly modifications on-site by matching exact floor conditions

Installation and Layout Flexibility

MEA manufactures each grating to match your installation plan. Whether the system requires flush edges, recessed profiles, or special locking mechanisms, MEA adapts the design to ensure both function and aesthetics align. You can also specify quick-lift access or permanent fastenings depending on maintenance requirements. Because MEA handles the engineering from start to finish, installation becomes faster and more predictable, even in time-sensitive construction phases.

FAQs

Q1: What customization options are available?

You can tailor length, width, thickness, surface finish, material grade, and drainage pattern.Q2: Can customized gratings support heavy vehicle loads?

Yes. MEA offers load classes from A15 to F900 to support everything from foot traffic to truck access.Q3: Is stainless steel the only material option?

For hygiene-focused applications, yes. However, we also offer options in ductile iron and composite materials for general use.Q4: How do I begin the ordering process?

Send us your technical drawing or site measurements, and our engineers will advise on specifications and provide a quotation.Q5: What is the typical lead time?

Depending on the design, production typically takes between 10 to 25 working days.Why Choose Customized Grating

MEA’s customized grating removes the limitations of off-the-shelf products. You get exactly what your project demands—no compromises. From hygienic spaces requiring smooth, bacteria-resistant surfaces to traffic zones demanding load resistance and stability, MEA delivers made-to-fit drainage solutions with precision, speed, and technical support. Our team works with you at every stage, helping you control costs while achieving performance and design goals.

-