Drainage Systems for Food Processing Plants | Hygienic Solutions

Food Processing Drainage Systems: Hygienic Solutions

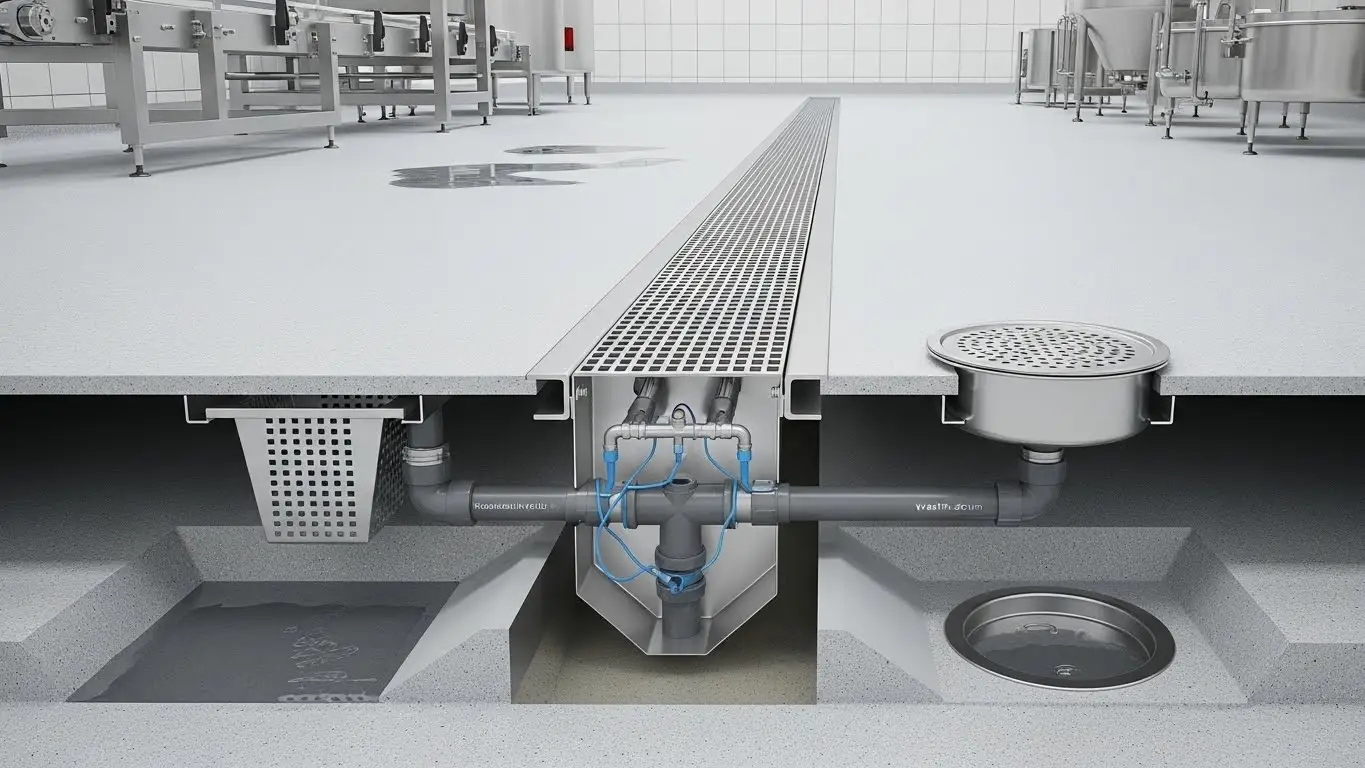

Sanitation, efficiency, and durability are important in the contemporary drainage systems for food processing plants. Whether it is a dairy plant or a meat processing one, whether it is a beverage factory or the kitchen of an industry, a proper drainage system guarantees hygiene, safety, and operational perfection.

- The companies that require the drainage system in food processing plants need to consider food-grade materials, anti-slip, large flow capacity, and corrosion resistance to conform to stringent industry requirements.

- As compliance with health and safety has been on the rise, the drainage systems on the food processing plant have become a major aspect in ensuring that the facilities are clean and productive. It could be a bakery production area, a beverage bottling plant, or a cold storage warehouse, but in any case, the modern industrial drainage system of food plants can provide efficiency with increased workplace safety. To get a complete portfolio of solutions, go to CMSA-MEA Products.

The Need for Hygienic Drainage Systems in a Food Processing Plant

There are stringent hygienic rules in the food industry. The ineffective drainage system may result in bacterial contamination, stagnant waters, and unhealthy working conditions. A designed hygienic drainage system can help solve these issues by providing:

- Floor drains that are sanitation-compliant.

- Large evacuation capacity with high throughput of water.

- Resistant to corrosion, such as stainless steel 304 and 316L.

- Bacteria-inhibitory, easy-clean designs.

- Connection with industrial floor plans.

Contemporary sanitized drainage systems in food processing not only eliminate food contamination but also simplify the cleaning process, which saves time and labor expenses.

Major Characteristics of Food Factory Industrial Drainage Systems

Material and Build Quality

The fabricated modern industrial floor drain systems are mostly of high-grade stainless steel (304 or 316L). This ensures:

- Cleaning chemical resistance to corrosion.

- Prolonged heavy-duty performance.

- Cleaning and easy maintenance.

Adherence to Food Safety Standards

As an illustration, MEA(r) Hygienic Ladder Grating is made of stainless steel 304/316L and optionally passivated, electro-polished, or sandblasted to be more durable and easier to touch.

Hygiene and Safety

The hygienic drainage systems are shaped such that they do not allow bacteria to grow the bacteria. Features include:

- Internal edges are rounded to reduce the accumulation of bacteria.

- Smooth weld-free surfaces

- The designs of anti-slip ladders help operate safely in wet conditions.

- Free spacing to facilitate the evacuation of liquids.

These characteristics are essential in conditions where sanitation and the safety of workers are the major concerns.

MEA(r) Hygienic Ladder Grating- Model BC-G200.500L(H-Ladder)

- Ladder design to allow effective drainage and support.

- Flat and no-welded finish in order to minimize the development of bacteria.

- Wet and sterile anti-slip design.

- Optional finishes: passivation, electro polishing, sandblasting.

- In accordance with EN 1253 (indoor) and EN 1433 (outdoor) standards.

Applications and Benefits

Food production space, commercial kitchens, laboratories, and clean rooms.

- Increases hygiene and decreases bacterial growth.

- Reduces the risk of slips and still allows free flow of water.

- Immune to cleaning substances and chemicals.

- Clean and maintainable easily.

Installation and Layout Flexibility

The gratings are blended with modular drainage channels in tiled, resin, or concrete floors. Bespoke sizing can be available to fit into the layout of a project, and removable covers can make cleaning and inspections easier.

Types of Drainage Systems in Food Processing Plants

- Hygienic Floor Drains

These sanitary floor drains are supposed to be used in wet processing areas, and they avoid bacterial contamination as well as ensure that water flows smoothly. Fits perfectly in dairy, meat, and beverage plants.

- Industrial Slot Drain Systems

Slot drains provide a low-profile solution with channel designs that are modular. Their sloping floors will allow them to drain fast without interfering with the aesthetics or safety.

- Food Plant Trench Drains

Trench drains are corrosion-resistant and used in high-traffic places where there is high water flow of water. They are ideal for sanitizing-heavy settings such as meatpacking and making drinks.

- Stainless Steel Drainage Trench

Stainless steel 304 or 316L is highly durable with respect to corrosion resistance, ease of cleaning, and conforms to food safety standards.

Technical Specifications Engineering Benefits

In choosing a drainage system in food processing plants, it should be:

- Large drainage capability to prevent stagnant water.

- Hardy cleaning chemicals are to be dealt with using materials resistant to corrosion.

- Foot and heavy equipment load-bearing channels.

- Efficient evacuation of water in anti-clog modular slot drain patterns.

- Optimization of floors slope to improve the performance of hydraulic drains.

- Food-grade safety, Sanitation-compliant systems.

Applications in the Food Industry

Drainage systems for food processing plants are flexible and are applied in various locations:

- Drainage in dairy processing plants is hygienic and chemical-resistant.

- Drainage system of meat processing plants- high flow and slip-resistant.

- Drainage flooring, Beverage and bottling plant floor-modular and easy to clean.

- Bakery production areas - stainless steel solutions that are corrosion-resistant.

- Wet processing zones - anti-clog and high flow channels.

- Cold storage drainage - sanitary and smooth surfaces.

- Wastewater management of food factories - effective surface water capturing.

- Installation of the industrial kitchen drainage - smooth connection with the floors.

Advantages of Hygienic Drainage Systems in Food Plants

Improved Cleanliness and hygiene: Avert bacterial growth and contamination.

- High Durability: Chemical and traffic-resistant.

- Low Operation Cost: Easy cleaning and maintenance-free design.

- Adjustable Layouts: Grating sizes are adjustable, and modular channels.

- Adherence to Standards: EN 1253 and EN 1433 are certified.

- Better Workflow: Elimination of water waste minimizes downtime.

The Reason to Select Certified Food Processing Plant Drain Suppliers

The choice of the supplier guarantees quality, durability, and compliance. Look for suppliers offering:

- Custom project solutions (OEM/ODM).

- Food-grade stainless steel channels.

- Slot drains and hygienic ladder gratings.

- Sanitation-compliant systems

- Drainage systems of the industry are of export quality.

Reliable suppliers, CMS, that do the technical support, installation advice, and services.

Conclusion:

Food processing plants no longer have merely functional modern drainage systems; they are hygienic, durable, and highly engineered. The ideal balance between safety, performance, and compliance is shown in such products as MEA(r) Hygienic Ladder Grating BC-G200.500L(H-ladder). Be it a dairy processing plant, a bakery, a meat processing plant, or an industrial kitchen, hygienic drainage systems are corrosion-resistant, and high-flow drainage systems offer operational efficiency, safety, and international standards compliance. Visit CMS.