Say Goodbye to Clogs With Smarter Floor Drainage Systems

In many factories and commercial kitchens, drainage is hidden under your feet, yet it controls hygiene, safety, and even production time. When it works, no one notices. When it fails, you face floods, bad smells, and emergency cleaning. Smarter floor drainage is not just a bigger channel or a nicer cover. It is a complete system that manages flow, cleaning, and safety together. So what actually makes a modern drainage system "smart” - and how can it stop clogs before they start?

Why Traditional Floor Drainage Systems Keep Letting You Down

Many older Floor Drainage Systems were designed for a different era. Production volumes were lower, cleaning routines were simpler, and hygiene rules were less strict. Those systems are now pushed far beyond what they were meant to handle.

Narrow channels struggle with high flow rates. Sharp corners and rough surfaces trap fat, food scraps, grains, and cleaning chemicals. Over time, these residues build up inside the drain until the water has nowhere to go. The result is familiar to many facility managers: blocked drains, unpleasant odours, and wet, slippery floors.

Each clog has a real operational cost. It is not just a puddle on the floor; it can trigger:

•Unplanned shutdowns of production lines or kitchen operations

•Pools of water that create slip and fall risks for staff

•Bacterial growth in corners that are almost impossible to clean

•Extra labour hours spent flushing, opening, and disinfecting drains

Hidden leaks create an additional layer of risk. In many older systems, joints and seals are weak. If the drain is not fully watertight, contaminated water can migrate into the surrounding concrete. Over time, the floor starts to crack, smell, or discolour. Repairs are disruptive and expensive, and hygiene problems become much harder to control.

For sectors under constant audit pressure - food, beverage, and pharma in particular - this is a serious headache. Even with strict cleaning schedules, a badly designed drainage system will keep undermining your efforts.

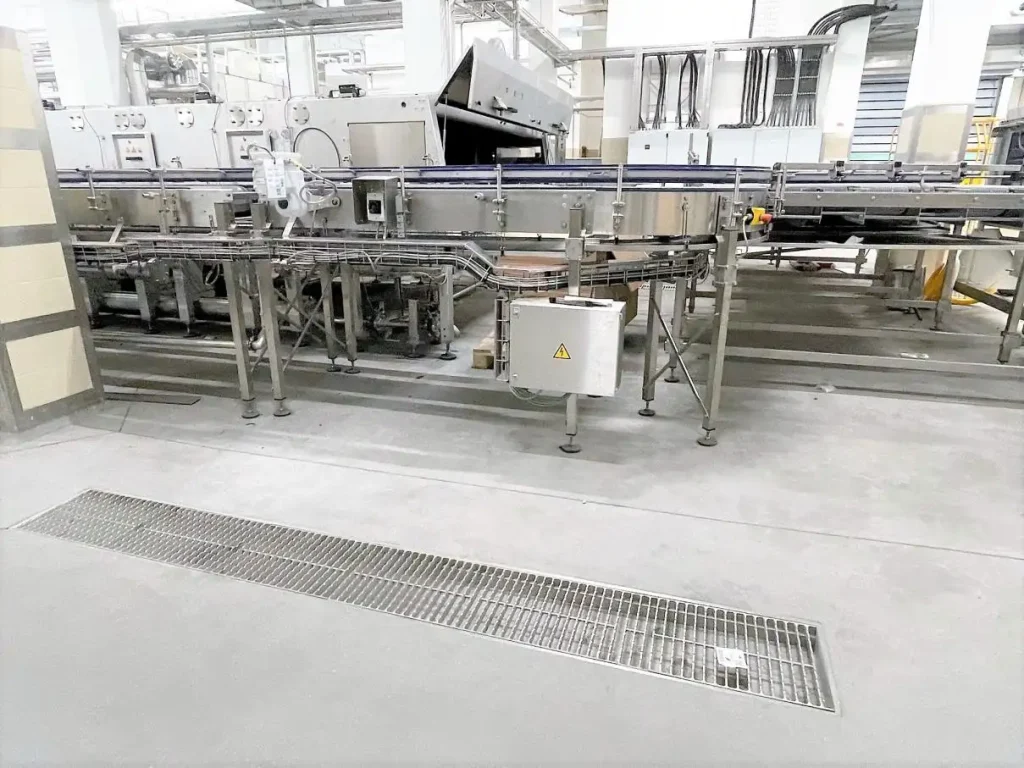

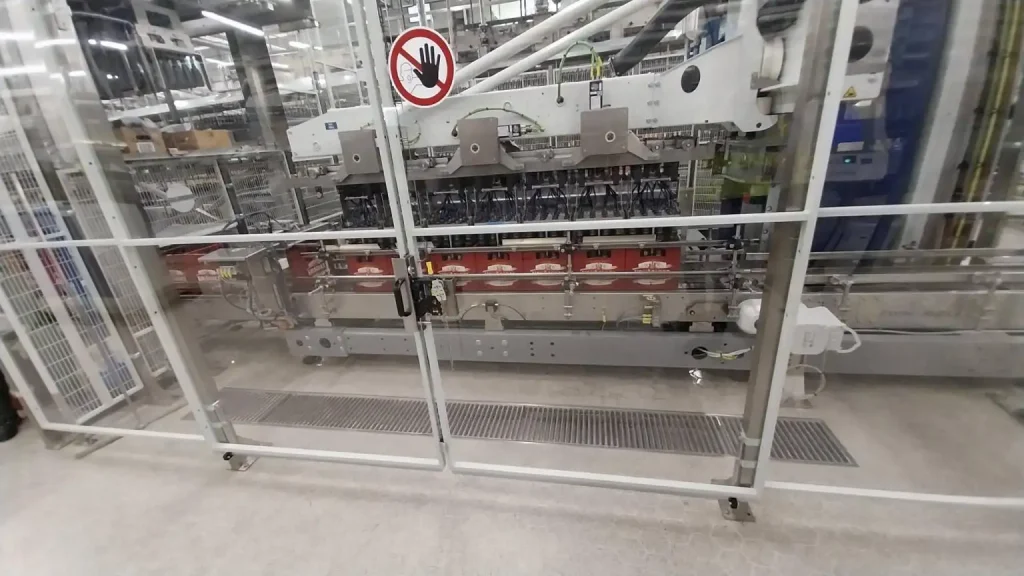

How CMSA Hygienic Floor Drainage Systems Break the Clog Cycle

At CMSA, we developed our hygienic stainless steel Floor Drainage Systems with one goal in mind: stop clogs before they form and make cleaning as simple as possible. Instead of just increasing the size of drains, we rethought the entire flow path - from the floor surface to the outlet - and how your teams interact with it every day.

- Intelligent Design for Clean, Fast Flow

The CMSA Hygienic Stainless Steel Drainage System combines modular channels, hygienic drains, and box channels that can be configured for each project. The focus is on smooth, uninterrupted flow:

•Large internal corner radii so residues have nowhere to hide

•Smooth internal surfaces that help water carry waste away efficiently

•Leak-proof construction to prevent hidden contamination in the slab

•Robust, impact-resistant edges that handle heavy traffic and equipment

•Optional anti-slip covers to improve safety in wet or oily areas

Because the system is modular, contractors can work with standardised components and still create layouts that match exact process lines, room shapes, and slopes. This speeds up installation, reduces rework on site, and makes future extensions to your facility much easier.

- Built-in Hygiene and Long-Term Durability

Material selection is critical in demanding environments. CMSA floor drainage systems are engineered in high-quality 304 or 316L stainless steel to give you:

•Reliable corrosion protection against food acids, harsh chemicals, and cleaning agents

•Safe performance at high temperatures for frequent hot-water and steam cleaning

Hygienic, low-roughness surfaces that are fast and simple to clean

•Fully recyclable materials to support your sustainability and ESG commitments

All CMSA hygienic stainless steel products carry EU CE certification and conform to EN1253 and EN16165.

The result: quicker approvals, less audit stress, and drainage that's already aligned with European hygiene and safety requirements.

- More Than Hardware: Engineering Support from Design to Handover

A good drainage concept does not start on site; it starts on the drawing board. CMSA supports your project with professional drainage engineering services, including:

•Drainage calculations using specialised software, with clear hydraulic reports

•Product selection tailored to project type, load class, and cleaning regime

•Detailed drainage layouts and product drawings to coordinate with other trades

•BIM object libraries and technical support for digital planning

•On-site training before installation and regular site checks during construction

When you combine intelligent design, robust stainless steel components, certified performance, and expert support, you are not simply buying drains. You are investing in a complete Floor Drainage System that is built to stay clean, stay safe, and stay in service.

What to Look for When Choosing Floor Drainage Systems

Selecting the right drainage solution becomes much easier when you know which questions to ask. At CMSA, we invite project owners, designers, and contractors to take a broader view than just comparing prices or channel dimensions.

Begin with the fundamentals: project type and load class. A large food processing facility with frequent forklift traffic places far greater demands on the system than a small restaurant kitchen. Think about both the mechanical stresses on the covers and the hygiene standards your process must achieve.

After that, assess the drainage performance. Will the system reliably manage peak volumes during wash-downs, cleaning routines, and potential emergency discharges? Undersizing here is a common cause of overflows and standing water.

Environmental conditions matter as well. If your facility uses aggressive chemicals, high temperatures, or experiences sudden hot - cold changes, stainless steel 304/316L is a reliable choice. It maintains its shape, surface quality, and hygiene performance over time.

Hygiene and maintenance are at the heart of any modern Floor Drainage System. Look for smooth internal radii, easy access for cleaning, and covers that can be removed and replaced quickly. If your team needs special tools, long shutdowns, or complex procedures just to clean a drain, that system will become a burden.

Modular design is another key factor. A modular drainage system:

•Speeds up installation and reduces on-site cutting

•Simplifies repairs and replacement of single sections

•Allows flexible layout changes as your production or menu evolves

Finally, do not overlook certifications, compliance, and customisation. CE marking and relevant EN standards help you meet local regulations. Customised components ensure that the drainage matches your floor build-up, slopes, and specific process zones instead of forcing you to compromise your layout.

When all these points are addressed together, you significantly reduce the risk of clogs, leaks, and hygiene failures over the full lifetime of the facility, not just in the first few years of operation.

Ready to Say Goodbye to Clogs?

If blocked drains, wet floors, and stressful inspections have become part of your daily routine, it may be time to rethink your drainage strategy. CMSA hygienic stainless steel Floor Drainage Systems give you a reliable, long-term solution supported by engineering expertise from concept to commissioning.

Whether you are designing a new factory or upgrading a single processing area, our team can help you define the right layout, capacity, and components to keep water - and only water - moving in the right direction.

Call to action:

Contact CMSA today to talk about your next project and discover how our hygienic stainless steel Floor Drainage Systems can help you finally say goodbye to clogs, downtime, and constant drain-related headaches.