Grease Separator Installation Cost | Kitchen Solutions

Grease Separator Cost Installation: Efficient Solutions

The wastewater in contemporary commercial kitchens, restaurants, food processing plants, and industrial kitchens poses a challenge that requires the management of fats, oils, and grease (FOG). Installing a good grease separator not only ensures that the sanitation regulations have been met but also prevents any blockage in the plumbing systems and expensive repairs. Knowledge of the cost of grease separator installation and the advantages of high-tech systems should be used by the decision-maker in the foodservice and industrial worlds.

The Reason it is Important to Invest in a Grease Separator

Oils, fats, and greases released into the drains may be deposited in the pipelines, thus leading to severe blockages, bad smells, and fines that are likely to be imposed by the local wastewater regulations. The cost of grease interceptor installations guarantees:

- Effective and secure wastewater management.

- Environmental and food safety regulation.

- Less interruption for maintenance and operation.

- Better hygiene and kitchen safety.

The characteristics of the modern commercial grease separator systems include built-in automation of the grease removal, self-cleaning brushes, heating, and microcomputerized controls, which ease the operations besides saving labor costs.

Variables That Will Influence the Cost of Grease Separators

The grease separator installation cost is dependent on several factors:

- Capacity Requirements

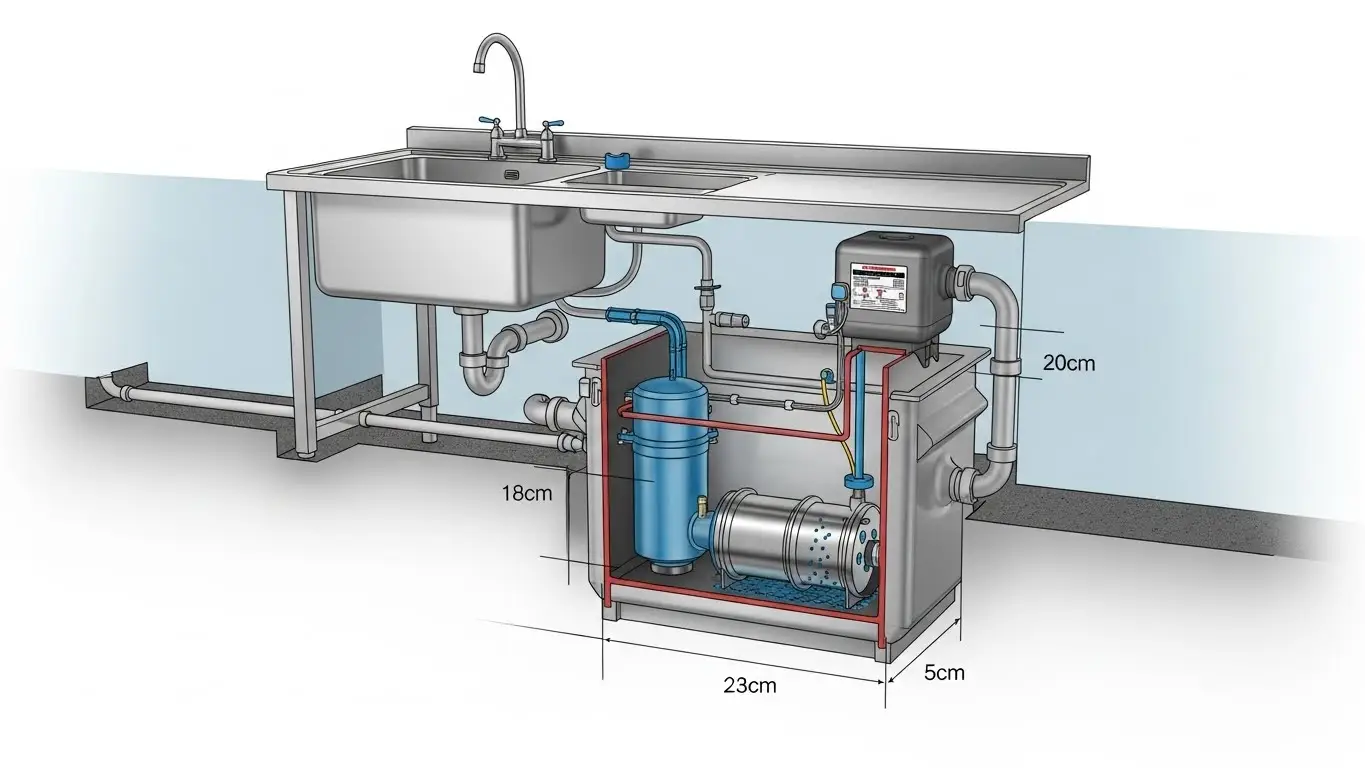

Nominal size of the grease separator is dependent on the size of the kitchen and the anticipated flow of the wastewater. As an example, the MEA Standard Grease Separation System (GS-2S). Measures 2 L/s, which suits well in medium to large commercial kitchens.

- Material and Build Quality

Stainless steel (SS304/316) construction is more resistant, durable, and long-lasting. Quality materials also somewhat raise the initial cost and save on the cost of maintenance in the long run.

- Automation Features

Self-cleaning brushes, heating, overflow sensors, and digital control built systems may require more to install, but they could also offer a lot of operational efficiency.

- Installation Complexity

Prices depend on the installation of a system into a new building or a retrofit into an existing kitchen. Small designs such as the GS-2S are easy to install in both cases.

- Optional Features

Additional expenses during initial costs include heating, odor-free sealed operation, and programmable microcomputer controls, which increase performance in high-demand kitchens.

MEA Standard Grease Separation System (GS-2S)

The MEA GS-2S is a grease separator that is industry-leading and combines durability, hygiene, and automation. This is to be used in restaurants, central kitchens, and food processing plants to effectively eliminate fats, oils, and grease in wastewater before discharge.

Key Features:

- Stainless steel (SS304/316) is not corrosive and can be used to sustain a long duration.

- Sealed non-smell operation aids in the kitchen odor escaping.

- Grease cleaner brush, self-cleaning, automated.

- Sludge that is >1.5mm will be removed effectively in a 2-stage separation.

- Elective warm-up in colder climates.

- Big sight glass and heated grease chamber to be easily monitored.

- A detachable design is used in channels >850mm with adjustable inlet/outlet.

- The microcomputer control is user-friendly and allows precise operation.

Technical Benefits of Higher Grease Separators

New industrial grease tapped and commercial kitchen grease separators have several engineering advantages:

- Optimization of the Hydraulic Flow

Guarantees steady grease collection and eliminates overflow during peak operations of the kitchen.

- Corrosion-Resistant Materials

Chemicals, cleaning agents, and high-temperature wastewater do not harm stainless steel or treated metals.

- Modular and Compact Designs

It can be installed in small areas and can be combined with already existing kitchen layouts.

- Automatic Grease Removal

Systems like MEA GS-2S have built-in self-cleaning brushes and microcomputer control, which minimize manual intervention.

- Load-Bearing and Durable

Grease separators of high volume are available as heavy-duty and can be used during high-volume kitchen operations without reducing the structural integrity.

- Maintenance-Friendly Features

Removable covers, sight glasses, and conveniently accessible parts make inspection and cleaning easier, thereby reducing downtime in operations.

Applications in Food Industry Sectors

The Grease separators play an essential role in various foodservice and industrial applications:

- Restaurants and Cafes: Grease pits: save on the cost of maintenance and blockage of pipes.

- Hotels and Catering Services: Compliance with the regulations of commercial kitchen wastewater.

- Food Processing Plants: Capable of high-capacity removal of grease.

- Bakeries and Central Kitchen: Have clean production areas and enhance hygiene.

- Industrial Kitchens: Guard plumbing and safeguard operations.

Advantages of Investing in a Quality Grease Separator

- Improved Hygiene and Safety

Removes grease on the floor, decreases slip hazards, and eliminates odor.

- Environmental Compliance

Complies with local requirements of wastewater discharge and does not face fines or sanctions.

- Operational Efficiency

Automates cleaning of the kitchen, reduces expenses on labor, and enhances workflow in high-paced kitchens.

- Long-Term Cost Savings

Although the cost of installing the initial grease separators may appear very high, it reduces the cost of blockages in the pipes, repair expenses, and labor in the long run.

- Flexibility and Scalability

Modular systems can be increased or expanded to come up with expanding operations.

Maintenance and Service Concerns

A grease separator does not require a lot of maintenance but needs regular checks to achieve the best performance:

- Washable, cleanable appliances such as self-cleaning brushes and sight glasses.

- Measure sludge buildup in two-stage separation chambers.

- Maintain automatic systems by having them serviced on a regular basis to avoid mechanical breakdowns.

- Clean the stainless steel using chemical-resistant cleaners.

Purchase of Equipment: Stainless Steel GS-2S of High Grade

- Plumbing and Installation of Inlet/Outlet Channels: Checking and installation of channels.

- Optional Automation: Microcomputer control, heating, and a self-cleaning brush.

- Maintenance Installation: First inspection and testing.

- An investment in a quality system will save in the long term through blocking and reduced manual cleaning.

Why MEA Grease Separation Systems?

MEA provides high-quality grease separators with the following characteristics:

- Durability made of stainless steel.

- One-touch grease removal requires a minimum of work.

- The cleaner kitchen environment operation is odor-free.

- Small and fit-in design to be installed anywhere.

- International standards and environmental regulations.

Conclusion

Knowledge of the grease separator installation cost is imperative in commercial kitchens, restaurants, hotels, and food processing plants. Big or small, cafe or factory kitchen, professional grease separator installation will be a cost that will pay itself in terms of better hygiene and lower maintenance needs, as well as in terms of being able to sustain sustainable kitchen operations. Visit CMSA.