How Good Drain Design Enhances Hygienic Drainage for Food Processing

Hygienic Drainage for Food Processing is not just about getting water off the floor; it is about protecting your products, your brand reputation, and the people working in your plant. At CMSA, we treat every drain as part of your hygiene concept, not as a small detail that disappears into the concrete. When drainage is designed well, cleaning gets easier, audits become less stressful, and you gain confidence that your floor is not hiding unwanted risks.

In today's food factories, production runs are long, and cleaning windows are short. At the same time, hygiene standards and customer expectations continue to rise. A poorly designed drainage system quickly shows its weaknesses: puddles around equipment, residues stuck in corners, unpleasant odors near outlets, and increased microbial risk in areas that are supposed to be clean. By contrast, a drainage system engineered for food environments supports your sanitation team, helps reduce downtime, and contributes to stable, repeatable food safety performance over many years.

Why Hygienic Drainage for Food Processing Starts with the Floor

Many hygiene problems in food plants begin at floor level. Water, fats, proteins, and sugars naturally run toward the drains, but they do not always leave the area as quickly as they should. If the channel has sharp corners, rough welds, or complex shapes, residues remain behind after each wash. Over time these residues build up, forming a perfect base for microorganisms. What looks like a small design compromise can quietly turn into a contamination hotspot.

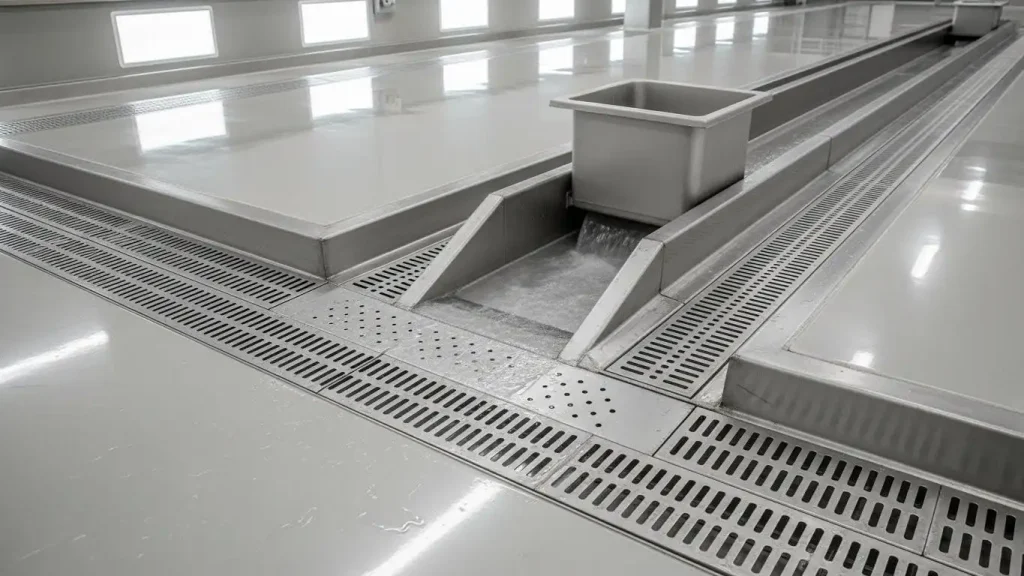

For this reason, Hygienic Drainage for Food Processing depends first on precise geometry and high-quality surfaces. Gentle transitions and generous internal radii help ensure that cleaning media can access all areas of the channel. When the channel bottom has a clear V-shape, liquids are guided directly toward the outlet instead of spreading across a flat base and stagnating. This self-draining effect makes it much easier to remove fine particles and organic matter during normal cleaning routines, even if your channels are long or slightly offset by equipment.

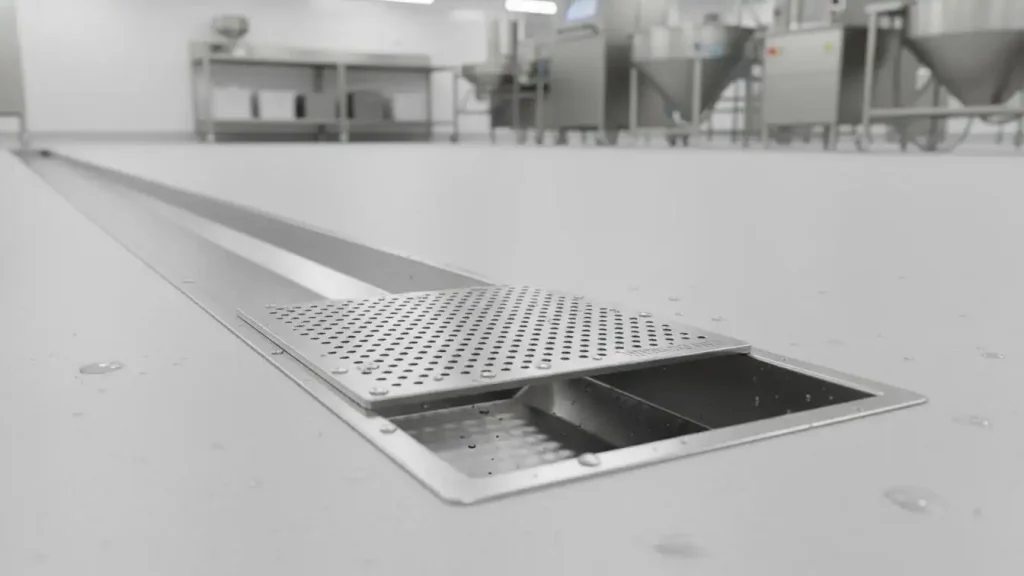

The interface between the channel and the surrounding floor is another critical zone. Traditional systems often leave gaps or weak edges where water can seep under the floor finish. CMSA addresses this with an infilled edge concept that stabilizes the frame and helps prevent local damage from trolleys, pallet trucks, or heavy loads. A stable, closed edge is not only more robust; it also reduces places where moisture and dirt can accumulate unnoticed. Combined with an internal design that avoids welded joints and rough seams, this creates a drainage system with fewer niches where bacteria can settle and grow.

How CMSA's Modular Box Channel Supports Hygienic Performance

CMSA has created its modular box channel system with a clear focus on Hygienic Drainage for Food Processing. The internal layout is optimised so that every surface can be reached and rinsed easily. Larger internal radii soften sharp edges, reducing the risk of residues clinging to the channel walls. The V-shaped base helps keep the channel as empty as possible when the line is not running, which CMSAns fewer stagnant zones and better overall hygiene between washdowns.

Durability is just as important as cleanability. Food plants are tough environments for floor drainage: high-temperature water, aggressive cleaning chemicals, frequent traffic, and sometimes thermal shock. CMSA uses stainless steel channel bodies that can be upgraded with different surface treatments, such as pickling, passivation, or electropolishing. These treatments help improve corrosion resistance and make surfaces even smoother, so residues adhere less and are easier to remove. In wet processing areas, slip-resistant gratings add a further safety layer by helping to reduce the risk of falls during production and cleaning, when floors are often wet and soiled.

Hygienic Drainage for Food Processing also depends on what happens below the floor. CMSA provides a wide selection of outlet units that can be combined with the modular channel system. Filters and baskets help catch solid particles before they enter the pipe network. Water traps are designed to reduce odors and stop air from the drainage system flowing back into the production space. At the same time, access for cleaning and inspection remains straightforward, so maintenance teams can work quickly and keep the system in a hygienic condition without complex disassembly.

Installation quality plays a large role in whether a drainage system performs as designed. CMSA's modular box channels are equipped with adjustable legs and anchor plates so installers can easily set the correct height and slope before pouring the concrete. Anti-deformation accessories protect the channel geometry during transport and installation, which CMSAns the system you receive on site matches the system that was calculated and designed. Where standard lengths or layouts do not fit your project, CMSA can supply custom-made elements to follow your exact floor plan, adapt to special equipment footprints, or meet specific load requirements.

For plant owners and operators, the result is a drainage solution that is easier to clean, more robust in daily use, and more predictable in terms of long-term hygiene and maintenance. In simple terms, you get a system that quietly does its job in the background, so your team can focus on production rather than firefighting floor problems.

✅Easier, faster cleaning routines

✅More stable hygiene in risk-sensitive areas

✅Longer service life and lower total cost of ownership

Design Support and Project Services from CMSA

Selecting a drainage solution is not just about choosing a channel size or grating type. Authentic Hygienic Drainage for Food Processing requires more than standard components - it needs a design that matches your operations, cleaning regime, and regulatory context. MEA partners with you to achieve this, bringing together technical expertise and practical support from design to installation.

Before any channel is installed on site, MEA works with you in the design phase to validate the drainage concept using professional hydraulic and capacity calculations. These studies determine the optimal channel dimensions, gradients, and outlet arrangement so that the system can handle real washdown conditions without overflow, while still remaining easy to access and clean. We review the specific application, from high-load production zones to lighter-traffic service areas, and recommend matching channel configurations, outlet solutions, and materials. For Hygienic Drainage for Food Processing, stainless steel is typically used in core process areas due to its high corrosion resistance and smooth finish, whereas complementary materials may be selected for non-critical or outdoor sections. To streamline the design process, MEA provides high-quality BIM content and exact product drawings tailored for use in your building or plant model. Coordinating drainage with all other trades at an early stage reduces the risk of installation clashes, repeated design changes, and additional project costs.

During installation, MEA can offer on-site training for contractors and maintenance teams to explain best practices for setting levels, fixing the channels, and protecting surfaces until handover. Throughout the installation process, we conduct systematic site reviews to check that the drainage solution is implemented as designed and all components are installed to specification. These visits also give us the chance to flag small issues early, when they can still be fixed easily. As the project closes, we actively support your inspection and acceptance procedures to confirm that the drainage system satisfies technical specifications and hygiene expectations. Because we stay involved from early design through commissioning, Hygienic Drainage for Food Processing is handled in a structured, transparent way, delivering a documented solution that fits your hygiene strategy and benefits from MEA's proven field knowledge.

If you are planning a new facility, expanding capacity, or refurbishing an older line, now is an excellent time to reassess your drainage. A well-designed MEA modular box channel network can help you clean more effectively, protect staff from slips and trips, and reinforce your food safety system over the long term.

Call to Action

Speak with MEA's drainage specialists about Hygienic Drainage for Food Processing in your plant. Share your process layout, cleaning regime, and risk zones, and we will help you develop a reliable, hygienic drainage concept that fits your production reality.