MEA Automatic Grease Trap

- Model: GS-7A

- Automatic Operation

- Two-Stage Separation

SS304/316 construction with customizable thickness. Features auto-running, two-stage separation, grease thickness detection, Siemens PLC, and easy-clean coated design. Durable, corrosion and heat resistant.

Specifications

| Model No. | GS-7A |

| Nominal Size | 7 L/S |

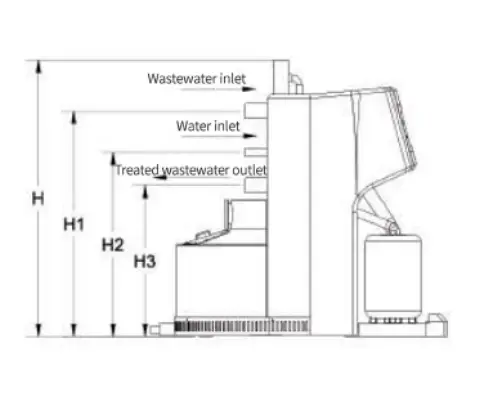

| Inlet/Outlet DN | 100 mm |

| Vent DN | 100 mm |

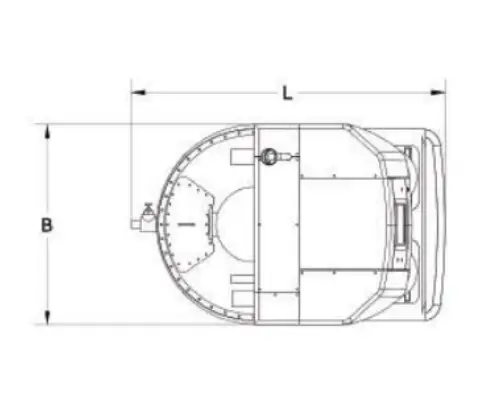

| B | 1360 mm |

| L | 2100 mm |

| H | 2000 mm |

| H1 | 1620 mm |

| H2 | 1300 mm |

| H3 | 1090 mm |

| Weight | 720 kg |

| Volume | 1100 mm |

For comprehensive information, please see the document available for download below.

-

Description

MEA automatic grease trap offers advanced grease and oil separation for commercial foodservice drainage systems. Designed for efficiency, this unit automates the separation and discharge of grease, improving sanitation while reducing manual maintenance. Its integrated heating and timing functions enhance oil discharge and reduce clogging risks. The automatic grease trap is ideal for operations that require continuous, hygienic wastewater treatment, such as restaurants, food factories, and central kitchens. By separating oil in real-time, it protects downstream piping, reduces cleaning frequency, and ensures compliance with environmental regulations.

Features

-

Stainless steel construction resists corrosion and supports long service life

-

Intelligent control with automated oil discharge cycle and timing functions

-

Internal heating device improves oil discharge in cold environments

-

Real-time grease separation ensures clean discharge and prevents blockages

-

No need for daily manual cleaning, minimizing labor and downtime

-

Compact design fits beneath or beside kitchen equipment

Applications and Benefits

-

Automatically separates and removes kitchen grease from wastewater

-

Prevents grease build-up in pipes and reduces service costs

-

Improves hygiene and kitchen operation efficiency

-

Supports regulatory compliance for commercial kitchens and food zones

-

Ideal for restaurants, cafeterias, food plants, and central kitchens

Installation and Layout Flexibility

The automatic grease trap installs quickly under sinks or in standalone grease control areas. Its compact body simplifies spatial planning, and the control panel allows remote or timed operation. Because the system automates collection and discharge, it reduces the need for complex maintenance routines. Technicians can monitor grease levels and discharge timing using digital displays, enabling predictive servicing. As a result, this unit works well in both new kitchen builds and retrofit projects.

FAQs

Q1: How does the automatic grease trap work?

A: It separates and stores grease continuously, then discharges it through an automated cycle using a timer and heater.Q2: What types of businesses use this product?

A: Restaurants, food factories, and any kitchen handling greasy wastewater benefit from automatic grease separation.Q3: How often does it require maintenance?

A: Unlike manual units, it needs only periodic inspections, not daily cleaning, which reduces labor needs.Q4: Can the system operate in cold environments?

A: Yes, the integrated heating element ensures consistent oil discharge in lower temperatures.Q5: Where should I install the grease trap?

A: You can install it under a sink, next to dishwashers, or in a central grease collection area.Why Choose Automatic Grease Trap

This automatic grease trap improves drainage hygiene, reduces labor, and boosts operational safety. The system performs continuous grease separation while scheduling discharges automatically, minimizing staff involvement. The stainless steel body ensures long-term durability and easy sanitation. Furthermore, its intelligent control module simplifies maintenance and supports different site conditions. Engineers and operators trust this solution for reliable, clean, and efficient wastewater management across foodservice and industrial settings.

-