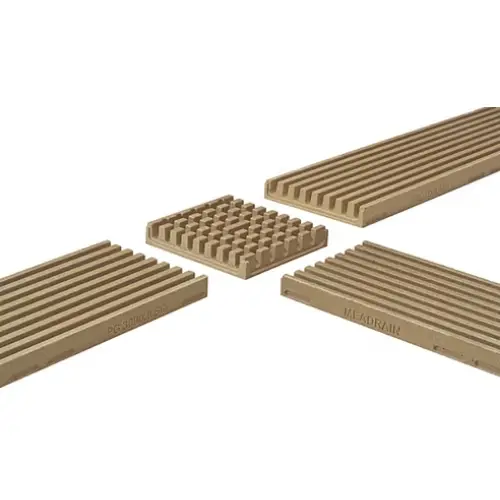

MEA®Ductile Iron Grating

- Model: 11A295

- Corrosion Resistant

- Anti-Rust Coating

There are many kinds of anti-rust coating on the surface of ductile iron grate, which has high anti-rust performance; a range of slot widths and styles are suitable for application scenarios with various drainage requirements.

Specifications

| Model No. | 11A295 |

| Material | Ductile iron |

| Compatible Systems | EN1000, U1000, Z1000, LZ1000/80 etc. |

| Width | 122 mm |

| Locking Mechanism | Standard, optional |

| Compliance | EN1433 |

| Loading Class | Up to F900 |

For comprehensive information, please see the document available for download below.

-

Description

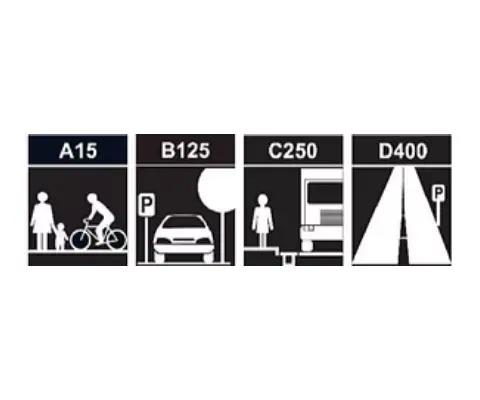

MEA ductile iron grating provides a high-strength, corrosion-resistant surface cover solution for advanced drainage systems. Engineered with premium anti-rust coatings, this grating resists wear from water, chemicals, and air exposure, making it ideal for long-term infrastructure use. Its adaptable slot widths and surface styles allow integration into systems like EN1000, U1000, Z1000, and LZ1000/80. With a width of 122 mm and a lockable mechanism option, ductile iron grating supports loading classes up to F900, meeting the most demanding traffic and industrial conditions. Whether installed in urban roads, transportation hubs, or industrial zones, it balances rugged performance with precise compatibility.

Features

-

High-performance anti-rust coatings enhance durability

-

Slot variations accommodate different flow and debris demands

-

Available locking system for secure installation

-

Complies with EN1433 standards for public safety and quality

-

Fits multiple MEA drainage channels including EN1000 and LZ1000

-

Rated up to F900 load class for extreme traffic conditions

Applications and Benefits

-

Performs in roads, airports, industrial yards, and loading docks

-

Protects drainage integrity with a secure and stable grating surface

-

Prevents rust damage and degradation over time

-

Compatible with linear drainage channels of varying widths

-

Offers high flow efficiency while minimizing blockage risks

Installation and Layout Flexibility

Installers can quickly integrate ductile iron grating into existing or new drainage systems using its standard width and lock mechanism. Its modular structure supports straight and curved layouts while resisting loosening under vibration or load stress. The grating’s surface coating provides long-term resistance to harsh environments, including coastal, chemical, or high-traffic zones.

FAQs

Q1: What makes ductile iron grating corrosion-resistant?

A: It includes multiple anti-rust coatings that protect the iron core from oxidation and environmental wear.Q2: Can I install it in heavy traffic areas?

A: Yes. It’s tested to F900 loading class, suitable for extreme vehicular loads.Q3: Does it fit with all MEA drainage channels?

A: It’s compatible with EN1000, U1000, Z1000, LZ1000/80 and others.Q4: Is a locking mechanism required?

A: Not always, but it's available for extra security where high impact or theft is a concern.Q5: How wide is the grating?

A: It measures 122 mm across, sized for standard channel systems.Why Choose Ductile Iron Grating

MEA ductile iron grating is the choice for professionals needing durable, heavy-duty surface covers that resist rust and match demanding drainage standards. It offers long service life, ease of maintenance, and secure fitting—ideal for infrastructure planners and drainage system integrators. From public roads to private facilities, it ensures safety, reliability, and performance in every installation.

-