MEA® Full Disposal Grease Separator Unit

- Model: GS-2W

- Easy Maintenance

- Efficient Cleaning

The MEA® Full Disposal Grease Separator features an integrated cleaning device and agitator, manual/automatic control, and an enclosed design to prevent odors. Double sightglasses enable easy monitoring, while the patented easy-clean design ensures simple operation and low maintenance.

Specifications

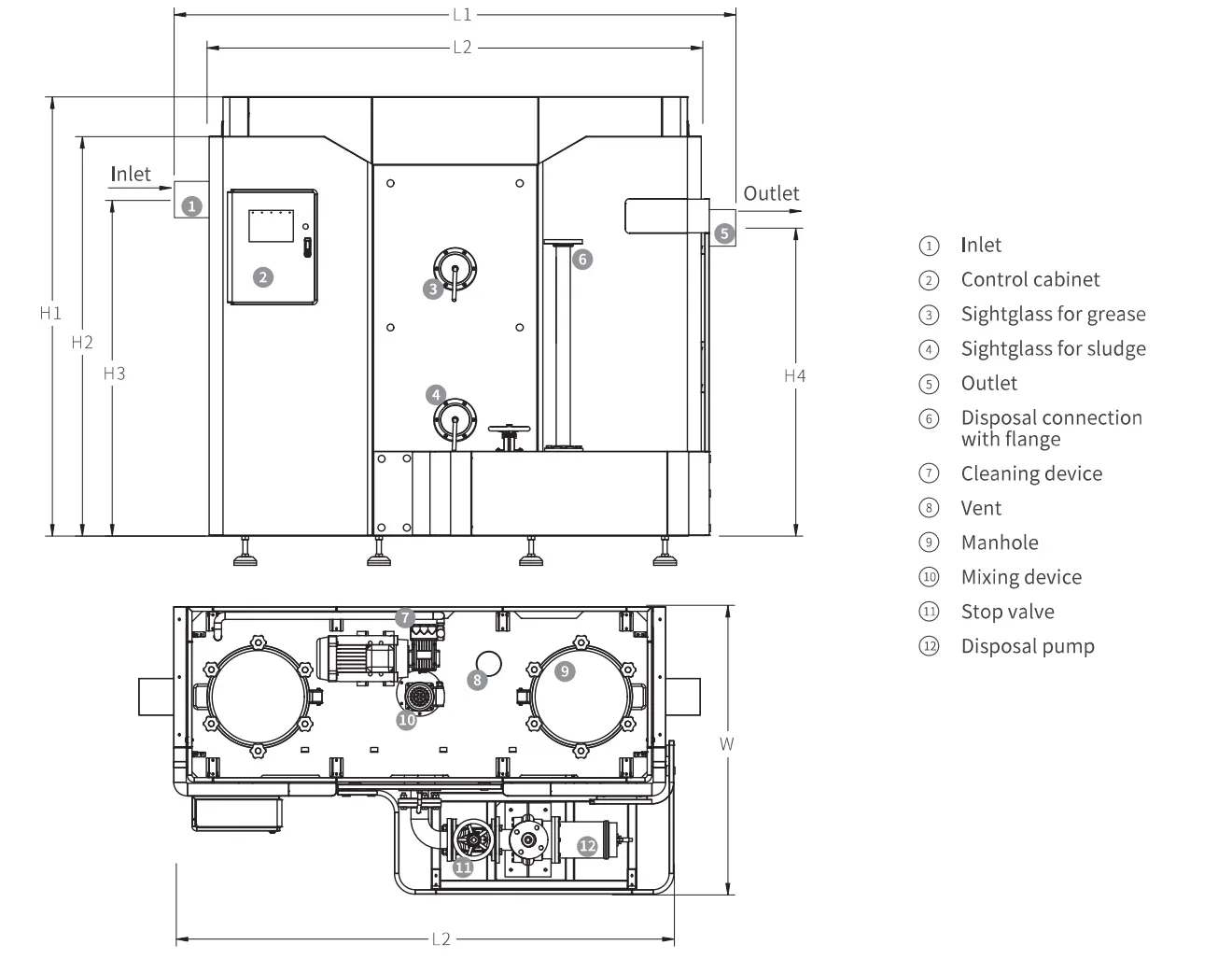

| Model No. | GS-2W |

| Nominal Size | 2 L/S |

| Inlet DN | 100 mm |

| Outlet DN | 100 mm |

| Vent DN | 100 mm |

| L1 | 2010 mm |

| L2 | 1710 mm |

| W | 1146 mm |

| H1 | 1515 mm |

| H2 | 1343 mm |

| H3 | 1095 mm |

| H4 | 1002 mm |

| Weight | 514 kg |

| Volume | 745 L |

For comprehensive information, please see the document available for download below.

-

Description

MEA full disposal grease separator unit provides a complete and sealed solution for grease separation, collection, and disposal. Designed for high-load commercial kitchens and food preparation zones, it integrates separation, agitation, cleaning, and disposal functions in one enclosed system. With both manual and automatic control modes, operators can easily adjust cleaning cycles based on kitchen flow conditions. The patented easy-clean design simplifies maintenance, while the enclosed structure ensures odor control and sanitation. MEA full disposal grease separator unit offers long-term durability and efficient operation under demanding conditions.

Product Characteristics

- Chamber thickness 2.5mm, durable

- Integrated separation chamber

- Enclosed running, no odor

- Double sightglass for grease and sludge

- Cleaning device and agitator

- Manual/automatic control mode

- Simple operation and maintenance

- Patented appearance, easy to clean

Product Accessories

- Made of stainless steel

- 400mm manhole

- DN100 vent port

- Double sightglass for grease and sludge, with manual cleaning handle

- Cleaning device and agitator

- Cleaning device with centrifugal pump

- DN65 disposal device, pump with cutting vanes

- Control cabinet

Product Size

Installation and Layout Flexibility

Full disposal grease separator unit installs smoothly into centralized kitchen drainage systems. The 400mm manhole allows easy internal access for service, while the DN100 vent port ensures pressure balance and safe ventilation. Thanks to its compact footprint and enclosed construction, it suits confined spaces without sacrificing performance. You can connect the disposal unit via DN65 port, supported by a pump with cutting vanes that breaks down and evacuates accumulated grease. This modular layout supports both new installations and retrofit upgrades.

FAQs

Q1: What makes this unit “full disposal”?

A: It separates, stores, and automatically removes grease via a sealed disposal pump system—no manual scooping required.Q2: How is odor controlled in this system?

A: The fully enclosed chamber, venting port, and sealed cleaning design prevent odors from escaping into the kitchen environment.Q3: Is maintenance time-consuming?

A: No. The easy-clean patent design and visible double sightglass make it quick to inspect and clean.Q4: Can I operate it manually?

A: Yes, the unit includes both manual and automated control modes for flexible usage.Q5: What materials are used in the construction?

A: The system is made entirely of stainless steel, including the cleaning components, control cabinet, and disposal pump.Why Choose Full Disposal Grease Separator Unit

Full disposal grease separator unit combines safety, automation, and hygiene in a compact package. Its integrated agitation and disposal functions allow kitchens to manage grease without exposure, odor, or downtime. Because the unit features stainless steel durability, a smart control cabinet, and double inspection windows, operators can easily maintain system performance. This unit solves multiple pain points—odor, labor intensity, and discharge compliance—making it the preferred solution for modern foodservice wastewater treatment.