MEA Standard Grease Separation System

- Model: GS-2S

- Enclosed Odor-Free Operation

- Self-Cleaning Brush

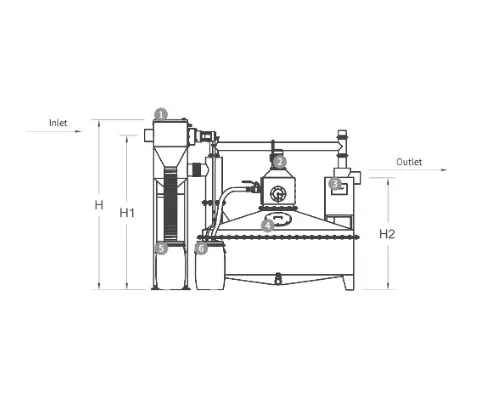

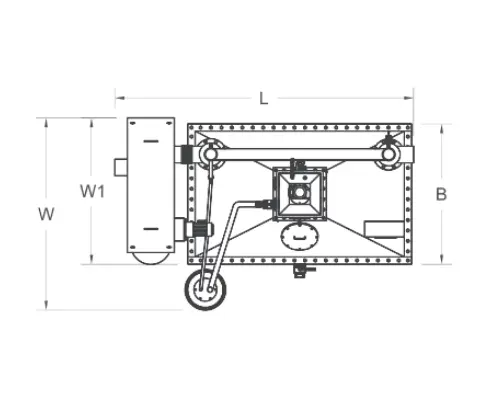

Customizable 2.5mm SS304/316 tank with large sludge chamber and two-stage separation removing sludge >1.5mm. Features self-cleaning brush, overflow sensor, optional heating, large sightglass, heated grease chamber, and odor-free enclosed operation. Detachable design fits >850mm channels with adjustable inlet/outlet. User-friendly microcomputer control.

Specifications

| Model No. | GS-2S |

| Nominal Size | 2 L/S |

| Inlet DN | 150 mm |

| Outlet DN | 100 mm |

| Vent DN | 100 mm |

| B | 845 mm |

| L | 2330 mm |

| H | 2130 mm |

| W1 | 1290 mm |

| W | 1440 mm |

| H1 | 1950 mm |

| H2 | 1360 mm |

| Weight | 550 kg |

For comprehensive information, please see the document available for download below.

-

Description

MEA grease separation system delivers continuous and automated grease removal for commercial foodservice operations. It separates fats, oils, and grease from wastewater in real time, ensuring clean discharge and protecting downstream plumbing. With a stainless steel structure and integrated heating, the system adapts well to high-temperature and variable-flow kitchen environments. As a result, the MEA grease separation system improves hygiene, reduces labor, and supports environmental compliance.

Features

-

Stainless steel construction resists corrosion and withstands heavy-duty usage

-

Built-in heating system maintains oil flow even in colder conditions

-

Real-time separation of grease prevents blockages and improves water quality

-

Digital control unit enables automatic timing and discharge scheduling

-

Compact body fits neatly under sinks or next to kitchen drainage lines

-

Minimal manual intervention required during regular operation

Applications and Benefits

-

Efficiently removes grease from wastewater before it enters drainage systems

-

Prevents odor, pipe blockages, and costly system maintenance

-

Reduces cleaning frequency while improving kitchen safety

-

Supports local compliance for grease waste disposal in foodservice zones

-

Works well in restaurants, central kitchens, and food processing plants

Installation and Layout Flexibility

MEA grease separation system installs quickly in a variety of kitchen setups. Thanks to its compact form and programmable features, it fits smoothly into both new construction and retrofit projects. You can configure the discharge cycle based on flow volume and kitchen workload. In addition, front-access maintenance panels allow quick inspection, so service teams can maintain performance without interrupting daily operations. This approach saves both time and space, especially in fast-paced commercial kitchens.

FAQs

Q1: How does the grease separation system function?

A: It actively separates grease from wastewater and automatically discharges it using scheduled control cycles.Q2: Can this system handle high-flow kitchens?

A: Absolutely. It’s designed for demanding foodservice environments with heavy grease loads.Q3: Does it require frequent manual cleaning?

A: No, it needs only periodic maintenance, which reduces labor and downtime.Q4: Is it suitable for cold kitchen conditions?

A: Yes, the heating element ensures smooth oil flow even at low ambient temperatures.Q5: Where should this unit be installed?

A: You can place it under a sink or near any wastewater outlet that handles greasy effluent.Why Choose Grease Separation System

MEA grease separation system gives commercial kitchens a durable, intelligent, and low-maintenance solution for managing grease waste. By combining automated operation with strong structural materials, it minimizes staff effort and ensures smooth drainage. Moreover, it enhances sanitation by preventing buildup and odor issues. Many foodservice businesses rely on this system to meet grease regulations, reduce plumbing issues, and maintain operational efficiency across busy kitchens.

-