Underground Grease Separator System: Efficient FOG Removal

Underground Grease Separate System: Complete Guide

Grease management has become one of the most important elements of hygiene, plumbing infrastructure protection, and environmental compliance in the contemporary foodservice and industrial environment. The mismanagement of fats, oils, and grease (FOG) in wastewater may cause obstructed sewer lines, bad smells, excessive repairs, and legal complications. In the case of commercial kitchens, large food processing plants, and large volume restaurants, an underground grease separator system installation is not only recommended, but a must.

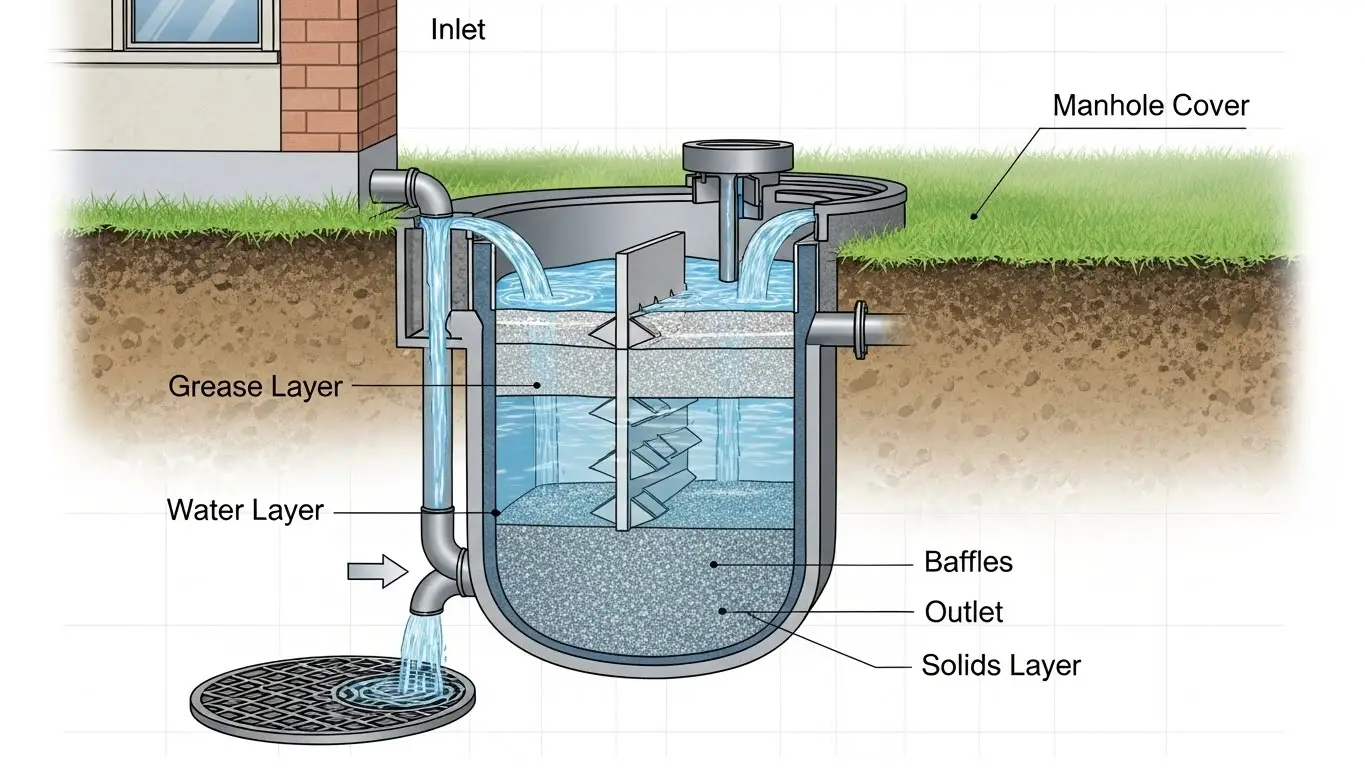

- Grease interceptor systems, also known as underground grease separator systems, subsurface grease separation systems, and commercial underground grease separators, are underground systems that are meant to effectively extract FOG in wastewater prior to its entry into municipal sewer systems.

- State-of-the-art models, including the MEA Standard Grease Separation System (GS-2S), offer compact, reliable, and automated packages to the kitchen and food service businesses.

Why are Underground Grease Separator Systems Necessary?

Kitchen wastewater and food processing facilities have high levels of fats, oils, and grease (FOG), which may solidify in plumbing and sewer systems. This can cause:

- Pipe blockages and backups

- Unpleasant odors

- High maintenance and operating expenses.

- Violation of environmental laws.

Through the introduction of a subsurface grease separator system, the businesses will be able to attain:

- The FOG removal systems of real-time wastewater treatment.

- Effective grease management in a commercial kitchen.

- Lightened work and cleaning schedule.

- Social responsibility and adherence to the local laws.

These systems are designed to meet high flow wastewater, grease separation, and interference with the operations are reduced. To substantiate this, the MEA GS-2S grease separator system integrates stainless steel, self-cleaning brushes, and computer-controlled microcomputer operation to maximize FOG control in commercial restaurant kitchens.

Types of Underground Grease Separator Systems

There are several different types of underground grease traps and separators that can be used to suit any industrial and commercial needs. Key types include:

Automatic Grease Removal Systems

Automatic systems are designed with inbuilt digital controls and programmable discharge cycles to separate FOG without manual control.

Benefits Include:

- Ongoing real-time separation.

- Reduced labor requirements

- Efficient management of FOG in high-temperature variable-flow kitchens.

- Small size to fit into the space.

Uses: Food Processing Facilities, Central Kitchens, and Restaurants

Construction with stainless steel provides resistance to corrosion, durability, and compliance with hygiene. The MEA GS-2S model has features such as:

- Self-cleaning brushes

- In-built heating to keep the grease flowing.

- Removable design to have flexibility in installation in channels more than 850mm.

Underground Grease Taps Concrete

Concrete grease pits are weighty and can accommodate big commercial and industrial premises. They offer:

- High-capacity FOG retention

- Extended life cycle and low maintenance.

- This is compatible with municipal drainage systems.

Uses: Cafeteria complexes, industrial kitchens, and food processing plants.

Hydro Mechanical Grease Separators (HMS)

HMS units have integrated grease removal and hydro mechanical engineering. They are designed for:

- Effective separation under variable flow.

- Small area of commercial kitchen designs.

- Adherence to local wastewater laws.

Applications: Restaurants, hotels, and cafeterias with high efficiency grease separation.

Technical Characteristics of Underground Grease Separators Systems

In the present times, the commercial underground grease separators have been developed using high-level engineering and materials to achieve high performance. The main technical characteristics are:

Material and Construction

- Tanks made of stainless steel are not corroded and are hygienic.

- The concrete or composite tanks afford a strong capacity for use in industrial activities.

- Self-cleaning brushes save on greasy buildup and result in manual maintenance being minimized.

- It has optional heating and ensures that FOG is in a liquid state to be removed continuously.

Separation and Retention

- Two-stage separation gets rid of sludge particles above 1.5mm in size, enhancing overall performance.

- Sludge chambers are large and can hold large volumes of FOG and decreasing the cleaning frequency.

- The design of grease retention tanks makes sure that the separation is constant even in times of peak flow.

Automation and Control

- The controlled operation enables programmable discharge cycles by using microcomputers.

- Sensors, including overflow sensors, guarantee safe working and prevent spillages.

- Front-access panels make inspection and regular maintenance easier and do not affect the productivity of the kitchen.

Flow Optimization

- Sizing and installation are done properly to avoid turbulence and ensure that FOG is removed efficiently.

- The inlets and outlets can be adjusted to suit the different rates of wastewater.

- The modular or detachable design enables it to integrate with other kitchen designs with ease.

Benefits of the MEA Standard Grease Separator System

MEA GS-2S model is designed to work with commercial kitchens and has a variety of benefits:

Durability and Corrosion Resistance

- Construction is made of stainless steel, which guarantees long performance.

- Appropriate for high-temperature wastewater.

- Durable to wear, chemical degradation.

Efficient and Automated Operation

- The recessed cleaner bottle avoids depositing.

- Autonomous discharge is operated by microcomputers.

- Online FOG separation enhances the quality of water.

Space and Flexibility Installation

- A detachable design is used in channels greater than 850mm.

- Inlet/outlet can be adjusted to suit any kitchen design.

- Small size that can be used in retrofit or new construction works.

Best Practices in Installation and Maintenance

- Determine Flow Requirements: Determine the maximum wastewater flow to make the grease separator appropriately sized.

- Choose the Right Type: Automatic, stainless steel, concrete, or HMS units that apply to the application.

- Install Underground Units with Proper Slope: Positioning of these units should be appropriate to remove FOG.

- Periodic Checkup: Diagnose the sludge and clean debris using front-access.

- Program Automatic Cycles: Set the discharge timetable depending on the workload in the kitchen to operate uniformly.

- Professional Installation: Compliance and efficiency with certified suppliers of the underground grease separator system.

Conclusion

The commercial kitchens, industrial facilities, and food service operations require the installation of a high-efficiency underground grease separator system. The MEA GS-2S grease separator is an advanced gadget that combines to provide a durable performance of stainless steel, an automatic and compact design, which allows the use of the system in most modern kitchens. To complete solutions, visit the entire line of grease separator systems and other products at CMSA MEA.