What High-Quality Linear Drains Mean for Long-Term Waterproofing

The High-Quality Linear Drains are more than just channels for water; they are a quiet but critical part of long-term waterproofing. In simple terms, they are slim, surface-level drains that collect and guide water away from sensitive areas. Wherever water can pool, they can work. But what do High-Quality Linear Drains really mean for the lifespan of your structure, your maintenance budget, and your waterproofing system? That is where the story gets interesting.

Why the Right Drain Decides the Life of Your Waterproofing

Waterproofing fails for simple reasons: water lingers, joints open, or chemicals attack the wrong material. Across airports, highways, city plazas, and buildings, we see the same pattern. Water tests every weak point. When drainage underperforms, membranes blister, slabs crack, and maintenance budgets swell. High-Quality Linear Drains change that sequence by giving water a fast, predictable path away from critical areas.

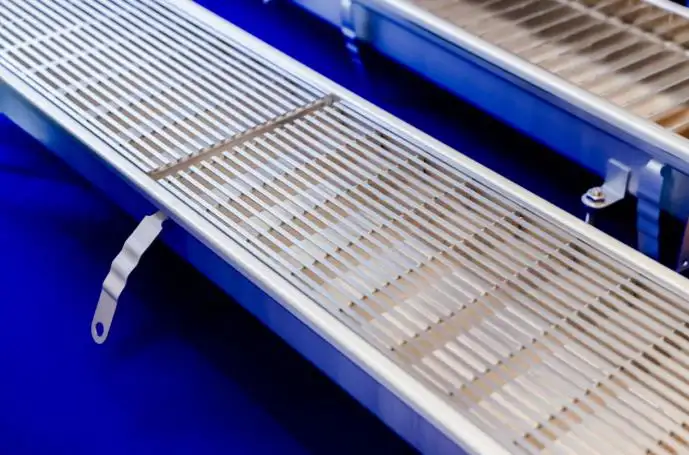

At MEA we start with polymer concrete because it behaves well under pressure - literally. The composite is dense, dimensionally stable, and strong under traffic loads. It is also low-porosity, which helps keep water and contaminants out of the body of the channel. In winter climates, the material stands up to freeze - thaw cycles; in transport hubs, it resists oils, de-icing salts, and other chemicals. The result is a drain that keeps doing its job long after traditional options lose shape or roughen and start trapping debris. Long-term waterproofing is not only membranes and sealants. It is the everyday reliability of the drain that protects them.

- Material Science That Works On Site

Specifiers ask for two things: longevity and fewer surprises. Polymer concrete helps deliver both. The smooth interior limits friction and makes cleaning easier. Recyclable content supports sustainability targets without trading away performance. By protecting groundwater and resisting chemical exposure, the system reduces the environmental and structural risks that creep into projects over time. For owners, this translates into fewer callbacks and better asset performance. For contractors, it means fewer reworks and faster handovers.

How MEA's Approach Lowers Lifetime Risk

The cost of water damage is more than a repair line item. It is downtime, safety exposure, and reputational harm. MEA designs High-Quality Linear Drains to reduce risk from the first drawing to years of operation.

• Modular, Lightweight Elements

Modular sections speed installation and reduce lifting strain. Crews align slopes more precisely, which keeps surface runoff consistent and prevents water from lingering near expansion joints or façade interfaces.

• Various Fall Possibilities

Sites are rarely simple. Ramps, transitions, and wide plazas need different falls along a single run. Our systems allow flexible slopes so water keeps moving and does not sit long enough to penetrate or attack adjacent layers.

• Almost Wear- And Maintenance-Free

Smooth internal surfaces limit debris adhesion. In practice, that means fewer blockages and fewer interventions. When maintenance is required, straight runs and accessible tops make it quick, predictable, and safe.

• Chemical Resistance

Runways face de-icing salts; parking decks see oils and fuel residue; city streets contend with detergents and urban runoff. Chemical-resistant polymer concrete protects the drain body - and by extension, your waterproofing system - from these daily exposures.

Beyond components, we invest in project coordination. Our team supports CAD, BIM, and design & calculation so the channel depth, slope, and outlet positions match structural and MEP realities. Most failures are prevented before a shovel hits the ground, and that coordination is where the prevention starts.

✅ Places Where The Gains Are Visible

- Airports and Terminals: Continuous capture along aprons limits standing water and spray, supporting runway and taxiway safety while protecting pavement layers.

- Highways and Bridges: Reliable edge drainage reduces splash and freeze - thaw stress, extending the life of wearing courses and joints.

- City Infrastructure: Linear intake in plazas and streetscapes protects paving integrity and keeps public spaces accessible during storms.

- Buildings and Podiums: Clean lines and steady hydraulics help façades and podiums stay dry, preserving membranes and coatings.

- Grates and Public Areas: Heel-safe, visually consistent tops protect users without slowing intake, keeping surfaces safe and attractive.

- Design Support That Prevents Failures

Early design choices decide decades of performance. Our engineers help size channels, verify flows, and select tops for traffic class and use case. We coordinate connection details so outlets, sumps, and waterproofing layers cooperate rather than compete. With the right drawings, crews build what the hydraulics require - not an approximation.

What Specifiers Should Check Before Approving A Linear Drain

High-Quality Linear Drains must match the risk profile of the site. A few checks go a long way toward long-term waterproofing.

1) Structure And Reliability Over The Whole Life

A polymer concrete body provides maximum resistance and reliability under heavy loads. Look for channels designed for industry and infrastructure - not just light duty. The drain should be the last thing you worry about as the surface ages.

2) Hydraulics You Can Actually Build

Perfect calculations mean little if crews cannot set the slope. Choose systems that support various fall possibilities and provide clear hydraulic data. When falls are consistent, water keeps moving; when it moves, it does not pry open joints or attack coatings.

3) Sustainability And Safety In One Package

Recyclable materials and features that help protect groundwater should be standard, not a premium feature. Combine that with chemical resistance and you mitigate both environmental and structural risk over the long term.

4) Serviceability Without Headaches

Access tops, simple interiors, and straight runs keep maintenance windows short. Facility teams need quick, safe routines - especially in terminals, bridges, and dense urban sites where closures are expensive.

5) Fit For Place, Not Just Fit For Purpose

Every project reads like a map: dominant winds, local rainfall intensity, traffic type, and surface materials. Our design team tailors High-Quality Linear Drains to those realities. In practice, that means the right grate for heel safety, the right channel for flow, and the right outlet strategy for clean tie-ins to storm networks.

Call To Action - Design For Durability From Day One

Bring us your plan set. MEA will review your drawings, share CAD/BIM files, and provide design & calculation support so High-Quality Linear Drains integrate cleanly with membranes, slabs, and outlets. Tell us the traffic class, rainfall data, and key constraints. We'll help you specify a solution that keeps water moving and structures protected.

Bottom Line

Long-term waterproofing is not a finish; it is a system decision. When the drain performs, membranes and coatings last. MEA's High-Quality Linear Drains - built from polymer concrete, engineered for flexible falls, and supported by robust design services - turn that principle into everyday performance. Specify early, coordinate details, and keep water where it belongs: moving off the surface and away from the asset, year after year.